BLOG

How to Choose the Best Lantech Stretch Wrapper for Your Needs?

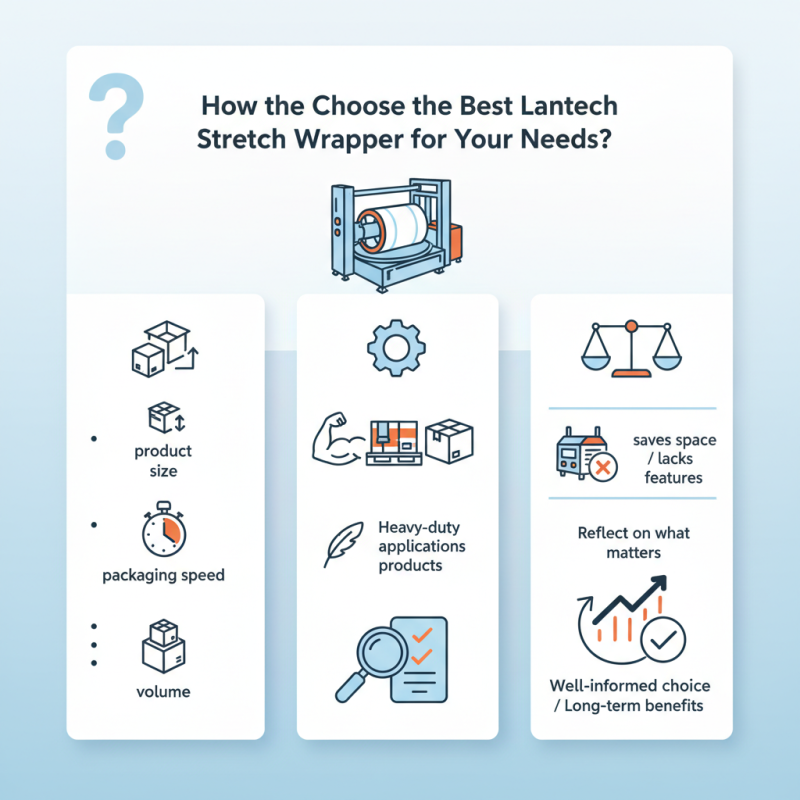

Choosing the right lantech stretch wrapper can be a daunting task. Various models offer different features. Your needs may vary based on product size, packaging speed, and volume.

Consider the efficiency of each model. Some lantech stretch wrappers are designed for heavy-duty applications. Others may cater to lighter products. Understanding your specific requirements is crucial.

It's also important to weigh the pros and cons. You might prefer a model that saves space. However, it could lack some features you find necessary. Thus, reflect on what truly matters for your business. Making a well-informed choice benefits you in the long run.

Understanding the Different Types of Lantech Stretch Wrappers

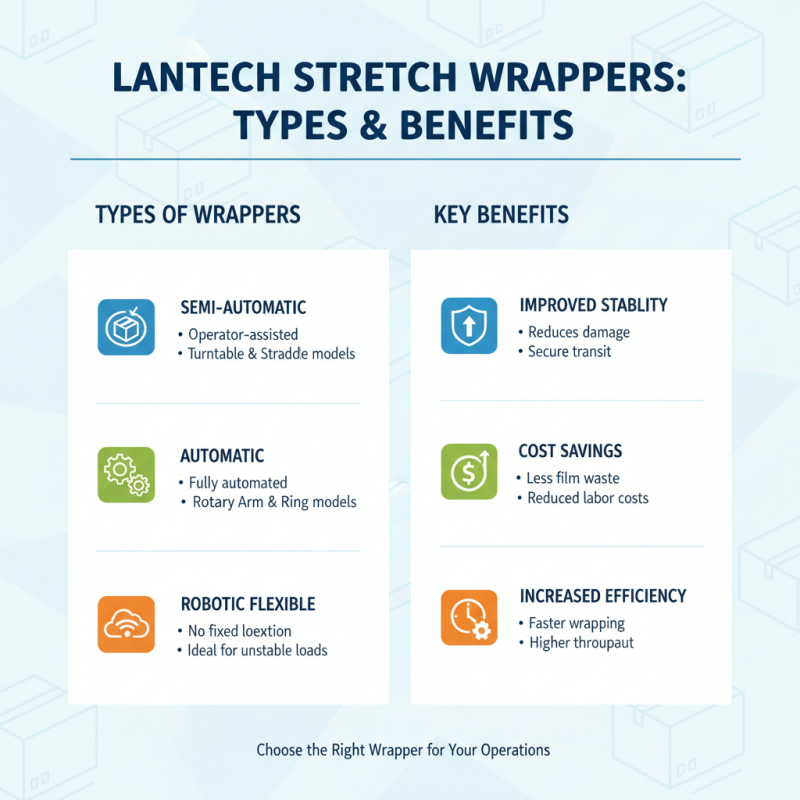

When exploring Lantech stretch wrappers, it’s essential to know the various types available. These machines are categorized based on their wrapping methods and automation levels. Understanding these types helps in making an informed decision that suits your operations.

Manual stretch wrappers are the most basic type. These machines require operators to wrap pallets by hand, making them less reliable for efficiency. In contrast, semi-automatic wrappers improve speed significantly. They often wrap an entire pallet with minimal operator input. According to a recent industry report, companies that switched to semi-automatic systems saw efficiency gains of up to 30%. Fully automatic stretch wrappers are at the top tier. They offer maximum productivity and consistency, reducing labor costs.

However, the choice depends on your specific needs. A warehouse with constant shipment might benefit from fully automated systems. But manual systems can be suitable for smaller operations. Nearly 40% of businesses report challenges in scaling their operations due to inadequate wrapping solutions. The decision should factor in your volume, space, and budget constraints. With these considerations, choosing the right type of Lantech stretch wrapper can streamline your packaging process.

Evaluating Load Sizes and Weights for Optimal Wrapper Selection

When considering a stretch wrapper, evaluating load sizes and weights is crucial. The right machine will depend on what you handle daily. Think about the various sizes of your loads. Are they consistently large or variable? If your products vary greatly, a flexible wrapper may suit you better.

The weight of your loads also matters. Heavier loads require more robust machines. Lighter products might not need the same level of protection. Ensure the chosen wrapper can handle both the weight and size of your goods. Each machine has its limits, and exceeding them can lead to issues.

**Tips:** Check the dimensions of your products and their typical weights. This will guide your selection. Additionally, consider how frequently you will need to wrap these loads. If it’s often, a faster model might be necessary. Whatever you choose, always reassess your needs periodically. What works now may not be ideal in the future.

How to Choose the Best Lantech Stretch Wrapper for Your Needs? - Evaluating Load Sizes and Weights for Optimal Wrapper Selection

| Load Size (inches) | Load Weight (lbs) | Ideal Wrapper Model | Wrapper Type |

|---|---|---|---|

| 48 x 40 | 2000 | Model A | Semi-Automatic |

| 60 x 48 | 2500 | Model B | Automatic |

| 72 x 60 | 3000 | Model C | Fully Automatic |

| 48 x 48 | 1500 | Model D | Semi-Automatic |

| 54 x 40 | 2000 | Model E | Automatic |

Analyzing Speed and Efficiency Features in Stretch Wrapping Machines

When selecting a stretch wrapping machine, speed and efficiency are crucial factors. High-speed wrapping leads to faster packaging cycles. It directly impacts productivity. Machines with adjustable speeds offer flexibility. You can tailor the wrapping process based on the product type. Some products require tighter wraps, while others do not. Failure to choose the right speed may result in inadequate packaging. This could lead to damaged goods.

Efficiency features also play a vital role in your decision. Machines with automatic film cut-off reduce manual labor. They save time and reduce film waste. Look for models that offer consistent wrap quality. Inconsistent wraps can lead to dissatisfaction and increased costs. Regular maintenance is essential to ensure optimal performance. Neglecting this can lead to inefficiencies over time.

Consider the learning curve of the machine operation. User-friendly controls can shorten training time. If staff struggle to operate the equipment, productivity suffers. It is essential to balance speed with ease of use. Sometimes, advanced features complicate operations. Streamlined processes often yield better results. Take time to assess your specific needs before finalizing any choice.

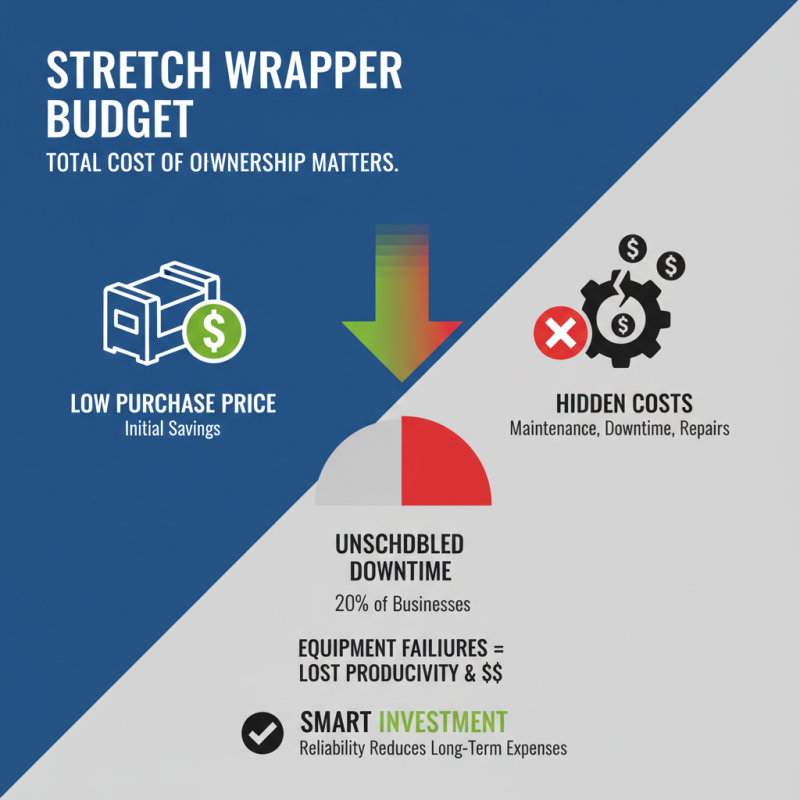

Determining Budget Considerations for Lantech Stretch Wrappers

Budget considerations are critical when selecting a stretch wrapper. Many companies often overlook the total cost of ownership. An inexpensive machine may lead to higher maintenance costs. This can quickly eat into your savings. According to a recent industry report, up to 20% of businesses experience unscheduled downtime due to equipment failures. This downtime can significantly impact your overall productivity and expenses.

When evaluating options, assess your production volume. A more robust machine may be necessary if your output is high. Lower-end machines may struggle under heavy loads, leading to frequent breakdowns. Understand the cost of repairs versus the initial investment. Reports indicate that businesses save 15% in yearly expenses by choosing a more reliable machine, even at a higher upfront cost.

Don't forget to consider operational efficiency. A stretch wrapper with automatic features can reduce labor costs. However, these features may increase the initial price. Some firms have found that investing in automation leads to a return on investment within a year. Balancing your budget with your operational needs is essential for long-term success.

Assessing the Importance of After-Sales Support and Warranty Options

When selecting a stretch wrapper, after-sales support is crucial. You want a provider who stands behind their product. Warranty options can provide peace of mind. Evaluate what’s included. A good warranty covers parts and labor for at least a year. Check for extended coverage too.

Consider the availability of customer service. How quickly can you get help? A responsive team prevents costly downtime. Regular maintenance can keep your machine running smoothly. Ensure you understand the support processes before making a decision.

Tips: Ask for testimonials from other users. See if they had any issues with support. You may find it helpful to discuss your specific needs with the provider. A tailored solution often proves more effective. Analyze your production requirements, and don't hesitate to voice your concerns. Address any uncertainties openly.

Related Posts

-

Top 10 Benefits of Using a Lantech Stretch Wrapper for Your Packaging Needs

-

How to Use Stretch Film for Effective Packaging and Protection?

-

Why You Need a Carton Erector for Streamlined Packaging Operations

-

10 Best Stretch Wrap Options for Packaging and Storage Solutions?

-

What is Pallet Wrap? Understanding Its Uses and Benefits for Shipping

-

What is Case Packing and How Does it Impact Your Shipping Efficiency