BLOG

The Future of Food Safety Revolutionizing Automated Food Packaging Systems

As the global demand for food continues to surge alongside a growing emphasis on safety and efficiency, the role of automated food packaging systems has never been more critical. These advanced technologies are not only streamlining packaging processes but are also enhancing food safety standards significantly. With the advent of smart sensors, robotics, and artificial intelligence, automated food packaging systems are revolutionizing the way food is prepared, packaged, and delivered. This transformation is crucial for minimizing human error, reducing contamination risks, and ensuring that products maintain their integrity throughout the supply chain. As we delve deeper into how these systems function and their implications for the future of the food industry, it becomes clear that the intersection of innovation and safety is poised to redefine our approach to food packaging and handling in unprecedented ways.

As the global demand for food continues to surge alongside a growing emphasis on safety and efficiency, the role of automated food packaging systems has never been more critical. These advanced technologies are not only streamlining packaging processes but are also enhancing food safety standards significantly. With the advent of smart sensors, robotics, and artificial intelligence, automated food packaging systems are revolutionizing the way food is prepared, packaged, and delivered. This transformation is crucial for minimizing human error, reducing contamination risks, and ensuring that products maintain their integrity throughout the supply chain. As we delve deeper into how these systems function and their implications for the future of the food industry, it becomes clear that the intersection of innovation and safety is poised to redefine our approach to food packaging and handling in unprecedented ways.

The Importance of Food Safety in Today’s Automated Packaging Landscape

In today's automated packaging landscape, food safety has become paramount as the industry rapidly evolves. As the automatic palletizing market is projected to grow from $758.17 million in 2023 to $1.15333 billion by 2031, reflecting a compound annual growth rate (CAGR) of 4.77%, the integration of advanced technologies in food packaging is essential to ensure product integrity and safety. Automated systems play a crucial role in minimizing human error and enhancing the efficiency of packaging processes, which are critical in maintaining the quality of perishable goods.

Moreover, the global food automation market is expected to increase significantly, from $8.983.3 million in 2025 to $12,200 million by 2033, with a CAGR of 3.9%. This growth signifies a shift towards precision and reliability in food processing and packaging, emphasizing the need for stringent safety standards that adhere to the evolving consumer demands. The reliance on automated systems not only enhances productivity but also reinforces the safety measures required to protect consumers from potential hazards, ultimately transforming the food industry into a safer and more efficient sector.

The Future of Food Safety: Automated Food Packaging Systems

This bar chart illustrates the importance of various factors in automated food packaging systems with regard to food safety. The scores represent how critical each factor is considered, with a scale from 1 to 10. Hygienic practices rank the highest, followed closely by temperature control and automation.

Key Technological Innovations Driving Automated Food Packaging Systems

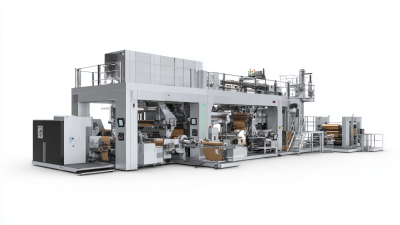

The landscape of food packaging is undergoing a remarkable transformation driven by technological innovations aimed at automating systems. As the demand for quality and personalized packaging rises, companies are increasingly adopting advanced solutions to enhance operational efficiency. The integration of automation within various sectors, including textiles, plastics, and healthcare, indicates a broader trend toward smart and sustainable practices in the food industry.

One of the key advancements in automated food packaging systems is the development of machinery that not only fills and seals products but also provides labeling and packaging solutions tailored to consumer needs. This evolution is crucial in the context of increasing competition and consumer expectations. As stakeholders embrace these innovations, they’re witnessing a significant boost in productivity and sustainability, which ultimately contributes to market growth.

Tip: When selecting automated food packaging solutions, consider the long-term benefits of sustainability and efficiency. Investing in advanced technology can enhance not only your production processes but also your brand’s reputation among environmentally conscious consumers.

Tip: Keep an eye on emerging trends in food packaging machinery that focus on digital transformation. Leveraging data analytics and IoT can lead to smarter decision-making and optimization of the supply chain, ensuring your business remains competitive in a fast-evolving market.

Impact of IoT and AI on Food Safety and Packaging Efficiency

The integration of the Internet of Things (IoT) and artificial intelligence (AI) into food packaging systems is set to dramatically enhance food safety and packaging efficiency. According to a report by MarketsandMarkets, the global smart packaging market is projected to reach $31.5 billion by 2026, with IoT-enabled solutions playing a crucial role in this growth. These technologies allow for real-time monitoring of food products throughout the supply chain, ensuring that necessary environmental conditions—such as temperature and humidity—are maintained to prevent spoilage and contamination.

AI algorithms can analyze data collected from various sensors embedded in packaging, predicting potential food safety hazards before they occur. A study published in the Journal of Food Science highlights that implementing AI-driven systems can reduce food waste by up to 50%, significantly benefiting both consumers and producers. Additionally, IoT devices can facilitate traceability, allowing stakeholders to track the origin and handling of food products, which is essential for compliance with increasingly stringent food safety regulations. As these technologies evolve, the combination of IoT and AI in automated food packaging systems will not only enhance safety measures but also contribute to improved operational efficiencies across the food supply chain.

The Future of Food Safety Revolutionizing Automated Food Packaging Systems - Impact of IoT and AI on Food Safety and Packaging Efficiency

| Dimension | Data Points | Impact on Food Safety | Efficiency Metrics |

|---|---|---|---|

| Temperature Monitoring | Continuous tracking data | Reduces spoilage risk | 30% more accurate |

| Smart Packaging | Integrated sensors | Enhances traceability | 40% decrease in waste |

| Automated Quality Control | AI-driven inspection | Early detection of contaminants | 50% faster processing |

| Supply Chain Transparency | Blockchain integration | Builds consumer trust | 25% more efficient logistics |

| Predictive Analytics | Data-driven forecasts | Proactive safety measures | 20% reduction in costs |

Data-Driven Approaches to Enhance Traceability and Quality in Food Packaging

The future of food safety is increasingly dependent on data-driven approaches that enhance traceability and quality in food packaging. As the organic food market continues to grow, with projections estimating a market size of $1178.1 billion by 2024, investments in automated food packaging systems are becoming essential. This growth is supported by the rise of consumer demand for organic products across various categories, including fruits and vegetables, dairy, meat, and beverages. With global food processing and handling equipment market expected to increase from $1237.5 billion in 2025 to $1895.1 billion by 2032, leveraging technology to improve food safety and packaging quality is paramount.

Innovations in smart packaging play a critical role in maintaining food integrity and safety. The smart packaging market, anticipated to grow from $26.06 billion in 2025 to $40.2 billion by 2032, emphasizes the necessity for advanced solutions that utilize data analytics for real-time monitoring. As food packaging evolves, organizations are focusing on sustainable practices and materials, aligning with consumer preferences for eco-friendly solutions. This shift not only enhances product traceability but also significantly reduces waste, contributing to a more secure and efficient food supply chain.

Future Trends in Sustainable Practices for Automated Food Packaging Solutions

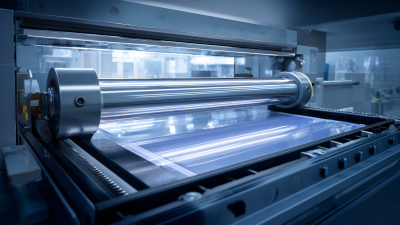

The future of automated food packaging is increasingly focused on sustainable practices that address environmental concerns while improving efficiency. Materials like polyethylene (PE) and polypropylene (PP) are at the forefront of this shift, as their recyclability and low environmental impact make them ideal for modern packaging solutions. Innovative production methods, such as blow molding and extrusion, are enhancing the capabilities of these materials, allowing for more efficient and environmentally friendly packaging options in the food service and pharmaceutical industries.

**Tips:** When choosing packaging materials, consider those with a higher recycled content. This not only reduces waste but often results in a lower carbon footprint during production. Additionally, explore the integration of RFID technology into reusable packaging. Such innovations not only improve inventory management but also enhance traceability in the supply chain.

As the global market for food automation continues to grow, the trend towards incorporating eco-friendly practices is becoming more pronounced. Companies are increasingly investing in sustainable technologies, paving the way for a greener future in food packaging. By leveraging advanced materials and processes, the industry is poised to make significant strides towards sustainability, ultimately benefiting both businesses and consumers alike.

Related Posts

-

The Future of Sustainable Packaging Equipment Innovations for Eco Friendly Solutions

-

Revolutionizing Efficiency in Automated Packaging Solutions for Modern Businesses

-

Optimizing Case Packing Efficiency: Insights from Recent Industry Reports and Best Practices

-

Exploring the Benefits of Using a Shrink Tunnel Machine for Enhanced Packaging Efficiency

-

Exploring the Benefits of Shrink Wrap Packaging for Sustainable Business Practices

-

The Ultimate Guide to Understanding the Benefits of an Automatic Pallet Wrapper