BLOG

Revolutionizing Efficiency in Manufacturing with an Automated Packaging Line for Sustainable Growth

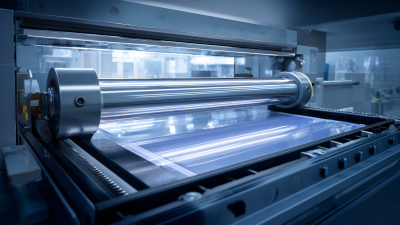

In the ever-evolving landscape of manufacturing, efficiency has become a paramount objective for companies seeking sustainable growth. One key area that has seen revolutionary advancements is the implementation of an automated packaging line. Industry expert, Dr. Emily Thompson, a leading authority in manufacturing automation, asserts, "Integrating an automated packaging line not only streamlines operations but also significantly reduces waste, resulting in a more sustainable production model." This perspective highlights the transformative impact of automation in optimizing manufacturing processes while fostering environmental responsibility.

The shift towards automated packaging solutions is not merely a trend; it represents a fundamental change in how businesses operate. By utilizing advanced technologies, manufacturers can enhance productivity, reduce labor costs, and minimize errors. Furthermore, the capability of an automated packaging line to adapt to varying product specifications ensures that companies can remain agile in a competitive market. As organizations increasingly recognize the benefits of automation, they are positioning themselves not just for immediate gains but also for long-term sustainability and profitability.

Transforming Traditional Manufacturing: The Role of Automation in Packaging

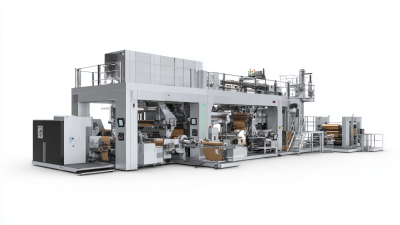

In the evolving landscape of manufacturing, automation in packaging is playing a pivotal role in transforming traditional practices into streamlined, efficient processes. The global packaging automation market is projected to witness substantial growth, expected to reach USD 3,278.4 million by 2035, fueled by increasing demand for efficiency and cost-effectiveness in production lines. As manufacturers adopt technologies such as machine learning and predictive analysis, the ability to minimize human error while enhancing productivity becomes a reality.

Moreover, the integration of advanced machine vision applications propelled by deep learning is revolutionizing quality control within consumer goods and packaging sectors. Traditional vision systems often fall short in ensuring product consistency and quality, while these new AI-driven solutions provide enhanced accuracy and speed.  This shift not only reduces operational costs but also significantly boosts profit margins, positioning companies for sustainable growth in a competitive market. As the automation arms race progresses, industries, including cannabis manufacturing, are leveraging smart systems to adapt and thrive, demonstrating the necessity for adaptation in today's fast-paced environment.

This shift not only reduces operational costs but also significantly boosts profit margins, positioning companies for sustainable growth in a competitive market. As the automation arms race progresses, industries, including cannabis manufacturing, are leveraging smart systems to adapt and thrive, demonstrating the necessity for adaptation in today's fast-paced environment.

Integrating Digital Solutions: Key Technologies for Automated Packaging Lines

The evolution of manufacturing efficiency is being fueled by the integration of digital solutions, particularly in the realm of automated packaging lines. According to a recent report by Smithers Pira, the global market for automated packaging technologies is projected to reach $100 billion by 2026, driven by the need for faster, safer, and more sustainable operations. This strong market growth highlights the significance of digital advancements in optimizing packaging processes, from design to delivery.

Key technologies such as IoT, machine learning, and robotics play a pivotal role in this transformation. For instance, IoT-enabled sensors can monitor machine performance in real-time, facilitating predictive maintenance and reducing downtime—an essential factor considering that unplanned downtime costs the manufacturing sector an estimated $50 billion annually (according to a report by IDC). Furthermore, machine learning algorithms enable smarter decision-making by analyzing data patterns, which enhances productivity and minimizes waste. By embracing these innovations, manufacturers not only improve efficiency but also contribute to sustainable growth, aligning with the increasing demand for eco-friendly practices in packaging.

Sustainability and Efficiency: Benefits of Environmentally Friendly Packaging

Sustainable packaging is becoming a cornerstone of efficiency in the manufacturing industry, particularly within food and pharmaceutical sectors facing increasing pressure to minimize environmental impact. As consumer demand for convenience grows, traditional packaging methods, especially those relying on single-use plastics, are being scrutinized. By adopting eco-friendly packaging solutions, companies can not only meet regulatory expectations but also align with the values of a growing base of environmentally-conscious consumers. This shift towards sustainable packaging can significantly enhance supply chain resilience and efficiency, creating a circular food supply chain that reduces waste through practices like reverse logistics.

Tips: Consider integrating biodegradable materials into your packaging solutions. Explore partnerships with suppliers who prioritize sustainability in their operations. Investing in smarter packaging design can also streamline logistics, reducing both costs and environmental footprint.

As the packaging industry embraces automation, the focus on sustainable practices is transforming the landscape. Companies are beginning to realize that sustainable packaging does not merely serve an eco-friendly purpose; it also yields substantial economic benefits. Research highlights that the financial potential of sustainable packaging can enhance brand reputation while driving operational cost savings, leading to long-term sustainable growth. By embracing these innovations, businesses can position themselves as leaders in sustainability, appealing to a market that increasingly values environmental consciousness.

Case Studies: Successful Implementation of Automated Packaging in Manufacturing

The implementation of automated packaging lines in manufacturing has demonstrated significant benefits, transforming operational efficiency and promoting sustainable growth. According to a report by Smithers Pira, the global market for automated packaging systems is expected to reach $85.9 billion by 2025, driven by the need for increased productivity and streamlined processes. One case study highlights a leading beverage manufacturer that integrated an automated packaging line, which reduced packaging time by 30%, allowing for quicker turnaround on production cycles without compromising product quality.

Furthermore, another instance involves a major electronics company that adopted automation within their packaging processes. This transition resulted in a 25% reduction in material waste, aligning with sustainability goals while simultaneously reducing operational costs. As per a study published by the International Society for Automation, such advancements have not only improved the speed and accuracy of packaging operations but also enhanced the overall safety of the manufacturing environment. These successful implementations illustrate the transformative impact of automated packaging on efficiency and eco-friendliness, establishing a new standard for the manufacturing industry.

Efficiency Improvements in Automated Packaging Lines

Future Trends: Innovations Shaping the Next Generation of Packaging Systems

The future of packaging systems is poised for transformative innovations that will define the next generation of manufacturing efficiency. According to a market report, the global advanced packaging equipment market is projected to grow from $981.256 million in 2024 to $2.670759 billion by 2032, indicating a significant shift toward automated systems that enhance productivity and sustainability in manufacturing. This growth reflects an increasing demand for smart packaging solutions that integrate seamlessly with e-commerce logistics, addressing the heightened expectations of consumers for both speed and sustainability.

As e-commerce continues to evolve, businesses must adapt to emerging trends that reshape the industry landscape. Key developments include the rise of automated packaging lines that not only streamline operations but also reduce waste, supporting sustainable growth initiatives. The report highlights 15 pivotal trends in e-commerce that are driving innovation, such as enhancements in supply chain transparency and the increasing use of artificial intelligence to optimize packaging processes. These advancements not only improve operational efficiency but also align with the industry's shift towards responsible consumption, thus creating a win-win scenario for brands and consumers alike.

Related Posts

-

Revolutionizing Efficiency in Automated Packaging Solutions for Modern Businesses

-

Exploring the Benefits of Shrink Wrap Packaging for Sustainable Business Practices

-

Exploring the Benefits of Using a Shrink Tunnel Machine for Enhanced Packaging Efficiency

-

The Future of Food Safety Revolutionizing Automated Food Packaging Systems

-

Revolutionizing Warehouse Efficiency: The Science Behind Automatic Pallet Wrappers

-

The Future of Sustainable Packaging Equipment Innovations for Eco Friendly Solutions