BLOG

2026 Top Types of Automatic Case Packers for Efficient Packaging Solutions

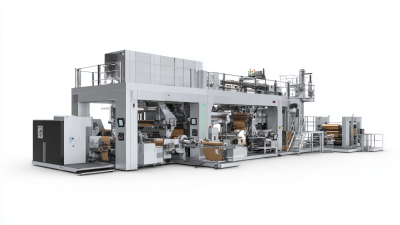

In today's fast-paced industry, the demand for efficient packaging solutions is ever-growing. An automatic case packer plays a crucial role in meeting these demands. These machines streamline the packaging process, saving time and reducing labor costs. With various models available, selecting the right one can be challenging.

Different types of automatic case packers cater to various products and packaging styles. Some packers handle fragile items, while others efficiently pack bulk goods. Each type presents unique advantages and potential shortcomings. It's important to evaluate efficiency against the specific needs of your production line. Often, the most sophisticated packers may not be the best fit for every situation.

As companies strive for optimization, a well-chosen automatic case packer can significantly impact productivity. However, it is also essential to reflect on the potential for technical malfunctions. Balancing automation with human oversight remains vital. Thoughtful consideration of these factors can ultimately lead to more informed decisions in equipment investment.

2026 Trends in Automatic Case Packers: An Industry Overview

The landscape of automatic case packers is shifting rapidly. As industries seek efficiency, adopting innovative technologies becomes vital. Manufacturers are focusing on integrating robotics into their packing processes. This integration enhances speed and accuracy, reducing labor costs significantly.

A key trend is the rise of flexibility in packaging solutions. Companies are now interested in machines that can handle various case sizes and types. This adaptability is essential in today's fast-paced market. However, challenges linger. Not all machines offer the same level of versatility. Some may struggle with more complex or unusual packaging requirements.

Furthermore, sustainability plays a crucial role in the 2026 trends. More companies are looking for eco-friendly packing materials. They also want machines that minimize waste. Yet, sourcing sustainable materials can be difficult. The industry must find a balance between efficiency and environmental responsibility. These evolving trends showcase both the potential and the challenges of automatic case packers in today's market.

Key Technologies Driving Efficiency in Automatic Case Packing Solutions

Automatic case packing is evolving rapidly. In 2026, efficiency in packaging solutions is more crucial than ever. Key technologies are driving this transformation. These advancements include robotics, vision systems, and artificial intelligence. Each plays a vital role in streamlining the packaging process.

Robotic arms excel in speed and accuracy. They handle delicate products without causing damage. They can quickly adapt to different sizes and shapes. Vision systems complement these robots by ensuring product alignment and quality. This synergy boosts overall productivity. However, implementing these technologies requires thoughtful planning. Training staff on new systems is critical. It can be a challenge, but it's worth the effort.

Tips: Always evaluate your current operations before upgrading. Identify bottlenecks and seek areas for improvement. Conduct regular training sessions for staff to stay updated with new technologies. Document all processes, as it helps in fine-tuning operations over time. Embracing automation is a journey that requires patience and persistence. Implementing efficient solutions can lead to significant gains, but not without some setbacks. Learn from them and keep evolving.

2026 Top Types of Automatic Case Packers for Efficient Packaging Solutions

| Type of Automatic Case Packer | Key Technologies | Efficiency Benefits | Applications |

|---|---|---|---|

| Robotic Case Packers | Artificial Intelligence, Vision Systems | High flexibility, reduced labor costs | Food, Beverage, Consumer Goods |

| Turntable Case Packers | Automated Conveyors, PLC Control | Fast throughput, compact design | Pharmaceuticals, Electronics |

| Wrap-Around Case Packers | Continuous Motion Technology | Minimal material usage, robust design | Beverages, Personal Care Products |

| Horizontal Case Packers | Servo Drive Technology | High speed packing, operational reliability | Food, Household Products |

| Vertical Case Packers | Smart Sensors, Automated Loading | Space-efficient, easy maintenance | Snacks, Pet Foods |

Comparative Analysis of Top Automatic Case Packer Models in 2026

Automatic case packers are essential for modern packaging lines. They streamline processes and improve efficiency. In 2026, a variety of models are available, each with unique features. Some packers provide high-speed operations while others focus on versatility. The choice depends on production needs and product types.

When analyzing case packer models, consider their speed and ease of use. Some machines are designed for specific shapes while others adapt to various packaging requirements. Look into user reviews and real-life performance data. These insights can reveal strengths and weaknesses. For example, how well does a machine handle fragile products?

Tip: Always conduct a trial run before full-scale implementation. This helps identify possible hiccups. Additionally, assess maintenance requirements. Machines that are hard to maintain can lead to unexpected downtimes. Choosing the right model is crucial for long-term success.

Market Growth Statistics: Demand for Automated Packaging Solutions

The demand for automated packaging solutions has been on the rise, driven by the need for efficiency. Industries are increasingly searching for ways to streamline their processes. One significant factor is the growing emphasis on reducing labor costs. Businesses want to minimize human intervention in packaging. This trend points to a clear market demand for automatic case packers.

Statistics reveal that the market for these solutions is expanding rapidly. Automating packaging can boost productivity and speed up the supply chain. Companies report significant time savings and reduced errors when using automated systems. However, some struggles remain. Many companies face challenges while integrating new technology into existing systems. Transitioning can be disruptive and require careful planning.

Investing in automatic case packers can lead to higher efficiency, but not all solutions fit every business. It's crucial to evaluate needs and capabilities. Each factory has unique requirements and potential hurdles. Sometimes, the promise of technology does not match the reality. Businesses must navigate these complexities to reap the benefits of automation.

Sustainability Considerations in the Design of Automatic Case Packers

Sustainability in automatic case packers is becoming crucial for manufacturers. Recent data shows that around 73% of consumers prefer brands that prioritize eco-friendly practices. Consequently, packaging machines are evolving. Designers are now focusing on reducing waste and optimizing energy consumption.

A study from the Sustainable Packaging Coalition reveals that packaging accounts for almost 30% of global waste. This drives innovations in machine technology. For instance, using eco-friendly materials can cut waste significantly. Implementing energy-efficient motors and reducing water usage in operations are other ways to enhance sustainability.

However, challenges remain. Not every machine efficiently integrates sustainability. Some designs may lead to higher initial costs. Some manufacturers may overlook the importance of lifecycle assessments. These assessments are vital. They can reveal potential hazards or inefficiencies in packaging processes. The journey toward sustainable packaging is ongoing. As the sector evolves, manufacturers must continuously assess and refine their systems.

Related Posts

-

What is a Case Packer and How It Transforms Your Packaging Process

-

The Future of Sustainable Packaging Equipment Innovations for Eco Friendly Solutions

-

Top 10 Benefits of Using Pallet Wrap for Secure and Efficient Shipping

-

Revolutionizing Efficiency in Automated Packaging Solutions for Modern Businesses

-

2025 Top Trends in Automatic Packing Systems for Improved Efficiency

-

What is Case Packing and How Does it Impact Your Shipping Efficiency